Elite Group for Construction is one of the main suppliers of garbage chutes in Saudi Arabia, they specialize in manufacturing and installing them in different residential and commercial projects. Let’s take a deep look into the details of these chutes.

What are garbage chutes?

Garbage chutes are vertical or inclined passages designed to efficiently dispose of waste materials from multiple floors of a building to a central collection point. They provide a convenient and centralized system for residents or occupants to dispose of their garbage without having to carry it down multiple flights of stairs.

These chutes are usually constructed of metal or fire-resistant materials and are designed to handle various types of waste, including general household trash, recyclables, and sometimes even compostable materials.

They also can contribute to better waste management practices by facilitating the separation of recyclable materials and promoting cleanliness and hygiene within the building environment.

What are their technical specifications?

Garbage chutes are usually constructed from durable and fire-resistant materials, such as metal or fire-rated plastic. The materials used should comply with safety and building codes.

- The dimensions of a garbage chute can vary based on the specific design of the building and the requirements of the waste management system. However, typical chute diameters range from around 16 inches (40 cm) to 24 inches (60 cm).

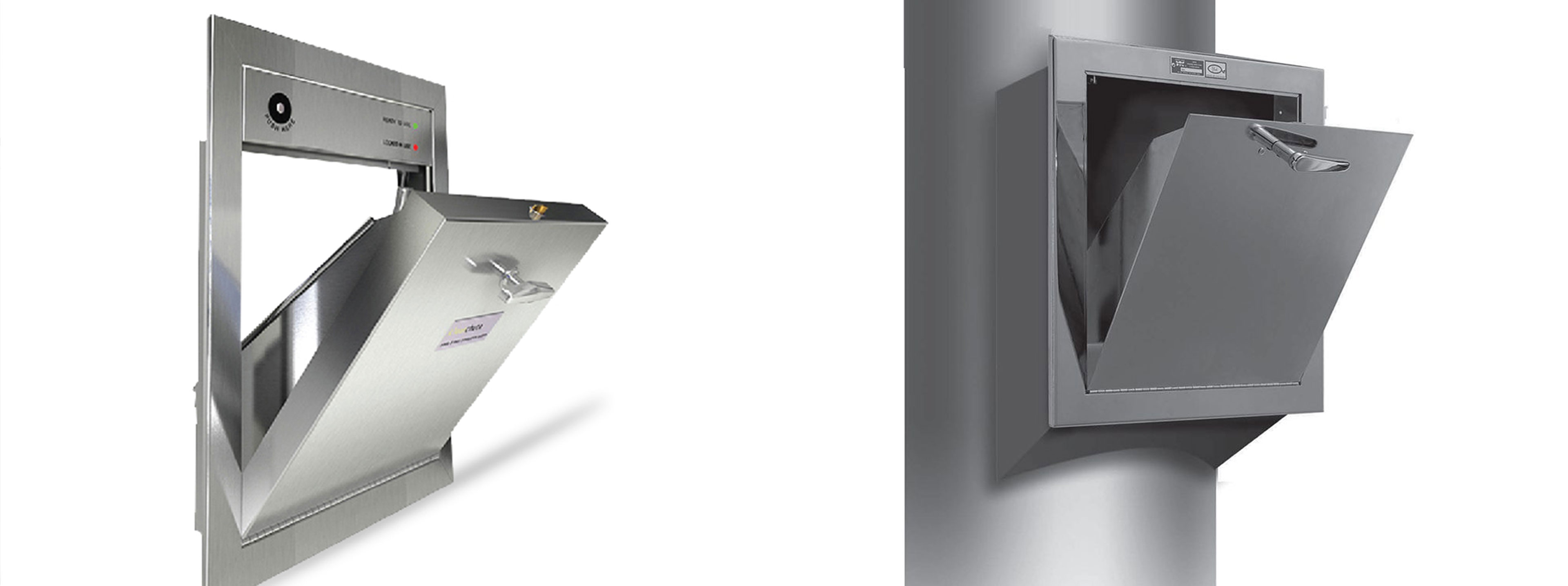

- Chute doors are typically part of the garbage chute entry points on each floor. These doors are designed to be self-closing to minimize odors and enhance fire safety. They are usually labeled to indicate their purpose.

- They often incorporate features to control odors, such as sealing systems on chute doors. Additionally, some systems may include ventilation to promote air circulation and minimize unpleasant smells within the building.

How do they work?

Garbage chutes work by providing a convenient and efficient method for disposing of waste materials from the upper floors of buildings to a central collection point at ground level. Here’s how they typically work:

- They are accessed through doors located on each floor of the building. These doors are usually equipped with a latch or handle that residents or occupants can use to open them.

- Once the access door is opened, occupants can access the opening of the garbage chute. This opening is typically covered with a hinged or sliding door that prevents odors and debris from escaping when the chute is not in use.

- Users can then deposit their waste materials, such as trash bags or recyclables, into the chute opening. It’s important to follow any guidelines or instructions provided to ensure that only acceptable materials are disposed of in the chute.

- Once the waste is deposited into the chute opening, gravity helps to carry it downward through the chute channel. The inclined or vertical design of the chute allows the waste to slide or fall freely toward the collection point at the bottom of the building.

- At the base of the building, the garbage chute typically empties into a collection bin, dumpster, compactor, or other receptacle designed to hold the waste until it can be properly disposed of or removed by waste management services.

- They are typically installed in multi-story buildings, including residential complexes, office buildings, hotels, and hospitals. They are commonly found in areas where a centralized waste disposal system is preferred to make waste management more convenient for occupants.

How they are manufactured?

Garbage chutes are typically manufactured using a combination of materials such as metal, plastic, or fire-resistant materials like concrete or fiberglass. The manufacturing process involves several steps:

- Designing the chute system according to the specific requirements of the building. Factors such as the height and layout of the building, the volume of waste generated, and local building codes and regulations are taken into consideration during the design phase.

- Depending on the design specifications and requirements, the appropriate materials are selected for constructing the garbage chute components. For example, the chute itself may be made of stainless steel, galvanized steel, aluminum, or high-density polyethylene (HDPE), while the access doors and other fittings may be made of plastic or metal.

- The chute sections are typically fabricated in Elite’s factory. For metal chutes, sheets of the chosen metal are cut, bent, and welded together to form the individual chute sections. For plastic or composite chutes, molding or extrusion processes may be used to create the desired shapes and dimensions.

- Once the individual chute sections are fabricated, they are assembled to create the complete garbage chute system. This may involve connecting the sections using bolts, screws, or welding, depending on the materials and design specifications.

- In addition to the chute sections themselves, various installation components such as access doors, support brackets, fire dampers, and safety features are also manufactured separately and assembled as part of the overall chute system.

- Throughout the manufacturing process, quality control measures are implemented to ensure that the garbage chutes meet the required standards for safety, durability, and performance. This may involve conducting inspections, tests, and certifications to verify compliance with relevant regulations and specifications.

- Once the garbage chute components are manufactured and assembled, they are packaged securely for transportation to the construction site.

- Finally, the garbage chute system is installed in the building according to the design plans and specifications. This typically involves attaching the chute sections to the building structure, connecting them to the access doors on each floor, and integrating any necessary support or safety features.